Even the most advanced production lines are only as reliable as their maintenance. At many manufacturing sites, field technicians face the deceptively simple question:

Which issues should I resolve first, and what troubleshooting steps should I follow?

What seems straightforward often turns complex—technicians must consult documentation, escalate to engineering teams, and dig through system logs and manuals just to diagnose and prioritize issues. This creates delays, repeated site visits, and increases unplanned downtime—all slowing down production and impacting output.

To tackle these challenges, our team turned business problem to solution using Agent Bricks Databricks’ platform for building high-quality AI agents on enterprise data and built a multi-agent system that delivers clear, actionable guidance to field technicians. In less than two days, I created a tool that equips maintenance teams with the real-time, contextual recommendations needed to resolve factory floor issues efficiently.

As a site reliability analyst this summer, I needed speed, simplicity, and accuracy. Agent Bricks let me rapidly build a robust solution that empowered technicians right at the production line.

Agent Bricks’ Multi-Agent Supervisor: Architecture

For manufacturing, the solution chains together three specialized agents under a Multi-Agent Supervisor:

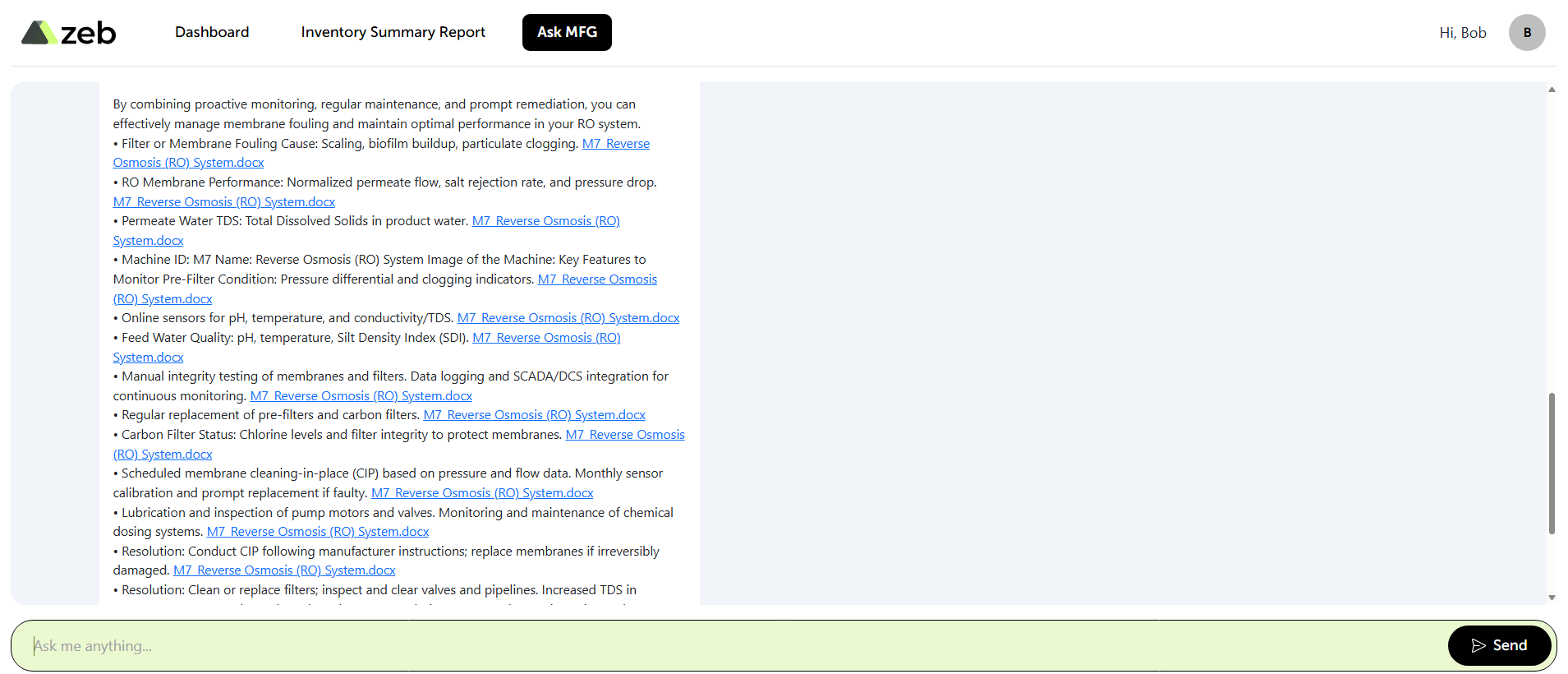

- Knowledge Assistant Agent Trained on internal maintenance manuals, engineering troubleshooting guides, and incident records (PDFs, slide decks, work instructions). This agent offers deep context for every problem type, guiding technicians with step-by-step troubleshooting and safety procedures. No need for manual parsing—documents are ingested in their original form

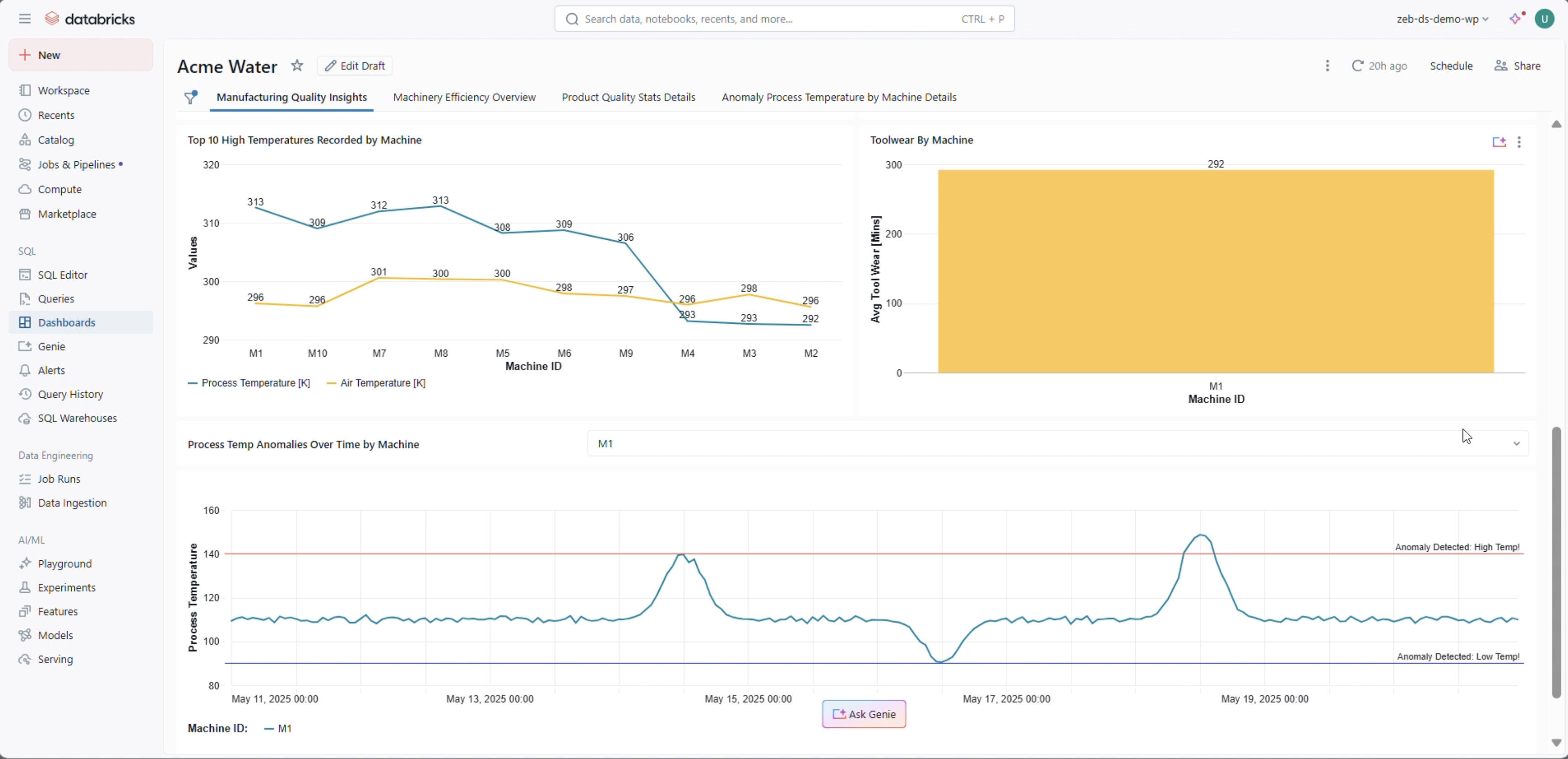

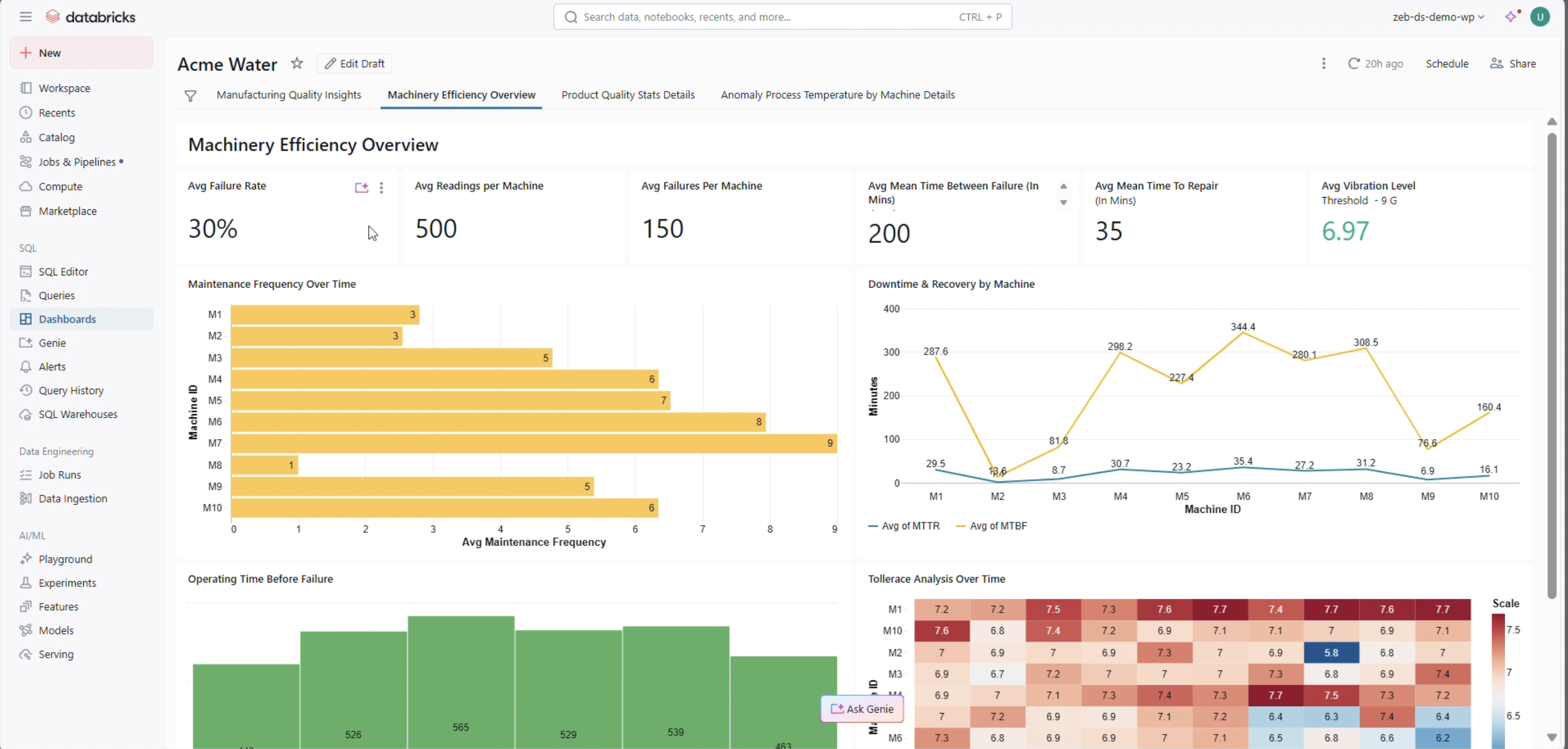

- Issue Analyzer Agent This agent analyzes structured machine telemetry and maintenance logs, governed by Unity Catalog, to pinpoint which equipment is currently affected, rank criticality, and flag the underlying root causes. It surfaces which diagnostic criteria are failed, suggests quick checks, and can display compliance with manufacturer guidelines on one screen.

- Prioritization Agent Drawing from live production schedules, downtime risk metrics, and asset health scores, this agent ranks issues by business impact. Field technicians receive an actionable, prioritized issue list—highlighting what to fix first for maximum operational efficiency.

The Supervisor operates like an orchestration hub: it takes the incoming maintenance request, delegates analysis to the right agent, and returns a unified, step-by-step resolution plan.

Key Benefits and Capabilities

- Technician Enablement Field staff get prioritized, explainable worklists—plus tailored troubleshooting steps—without chasing documentation or escalating to engineers. All critical safety, compliance, and diagnostic information appears directly where it’s needed.

- Seamless Scaling As new machinery, sensors, and production lines are added, the system updates insights automatically. Maintenance guides and SOPs are refreshed with new uploads; no code changes required.

- Integrated Decision Support Automated chaining of structured machine data and unstructured engineering documentation provides comprehensive support while minimizing error and delay in issue resolution.

Here is the real time example

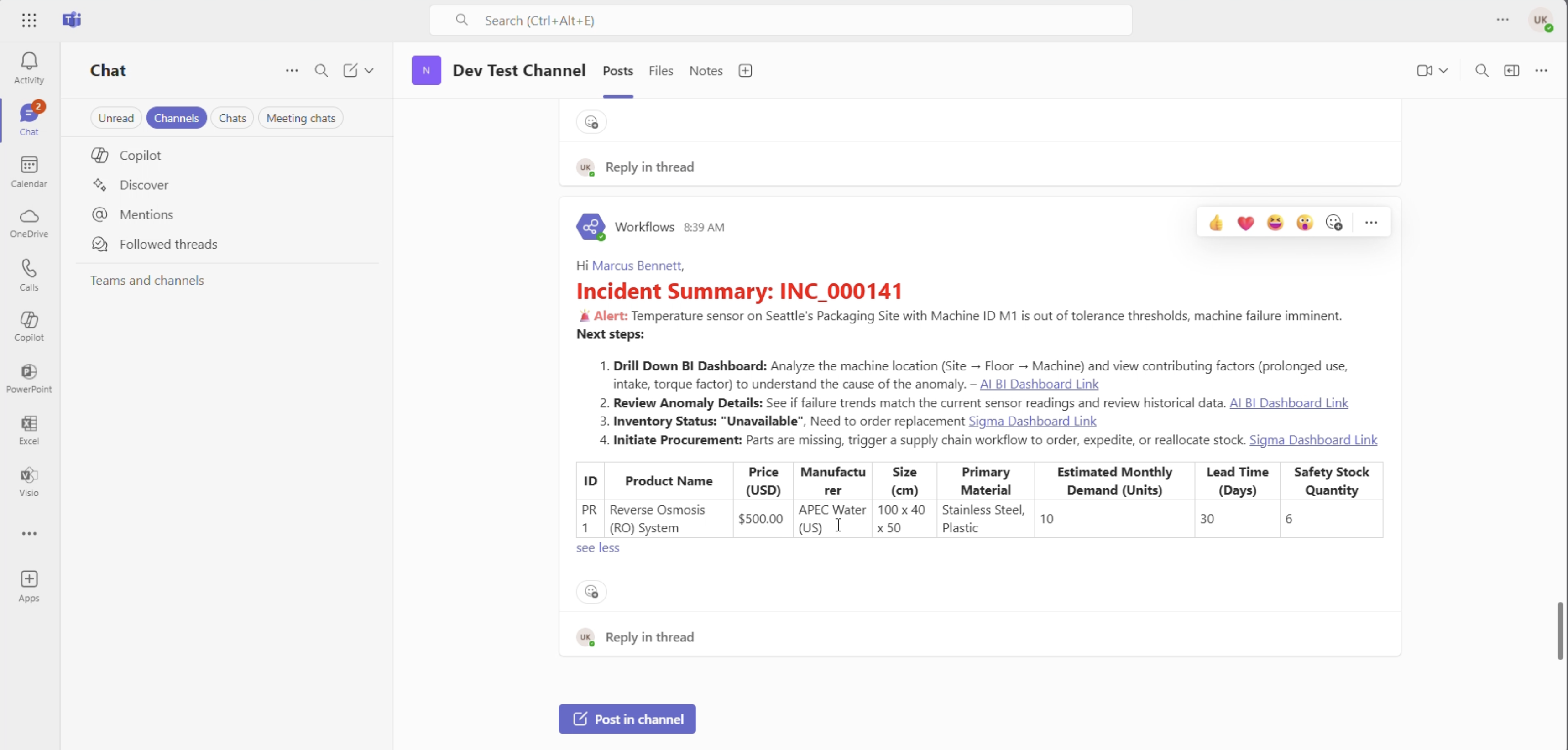

On the manufacturing floor, even small anomalies can disrupt operations. At the Seattle Packaging Site, Machine ID: M1 on floor 2 begins showing unusual readings, torque and temperature levels exceeding preset thresholds.

Immediately, a real-time alert is sent to Microsoft Teams, notifying the maintenance team with the recommended next action: “Maintenance is indicated.” Alongside this alert, Agent Bricks provides context-aware guidance, pulling step-by-step instructions from internal SOPs, manuals, and troubleshooting documents.

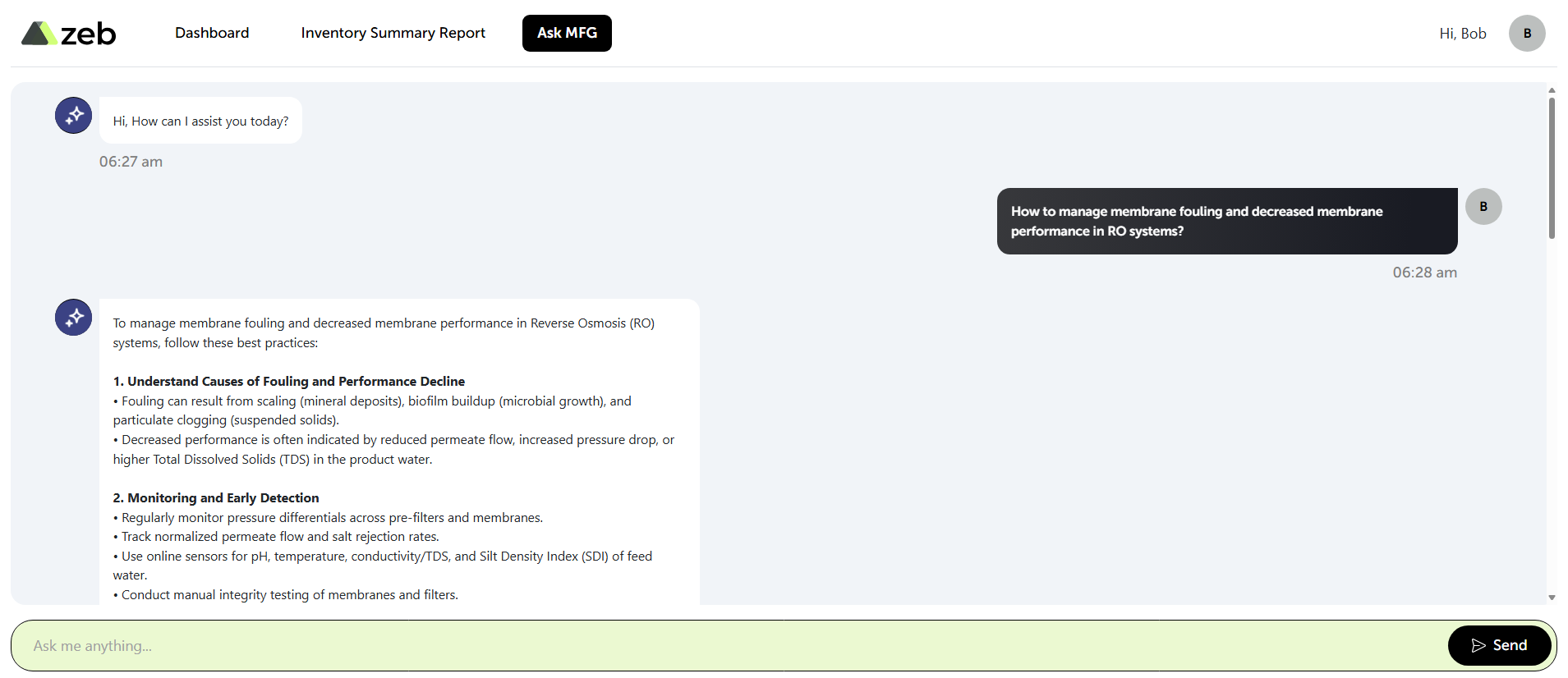

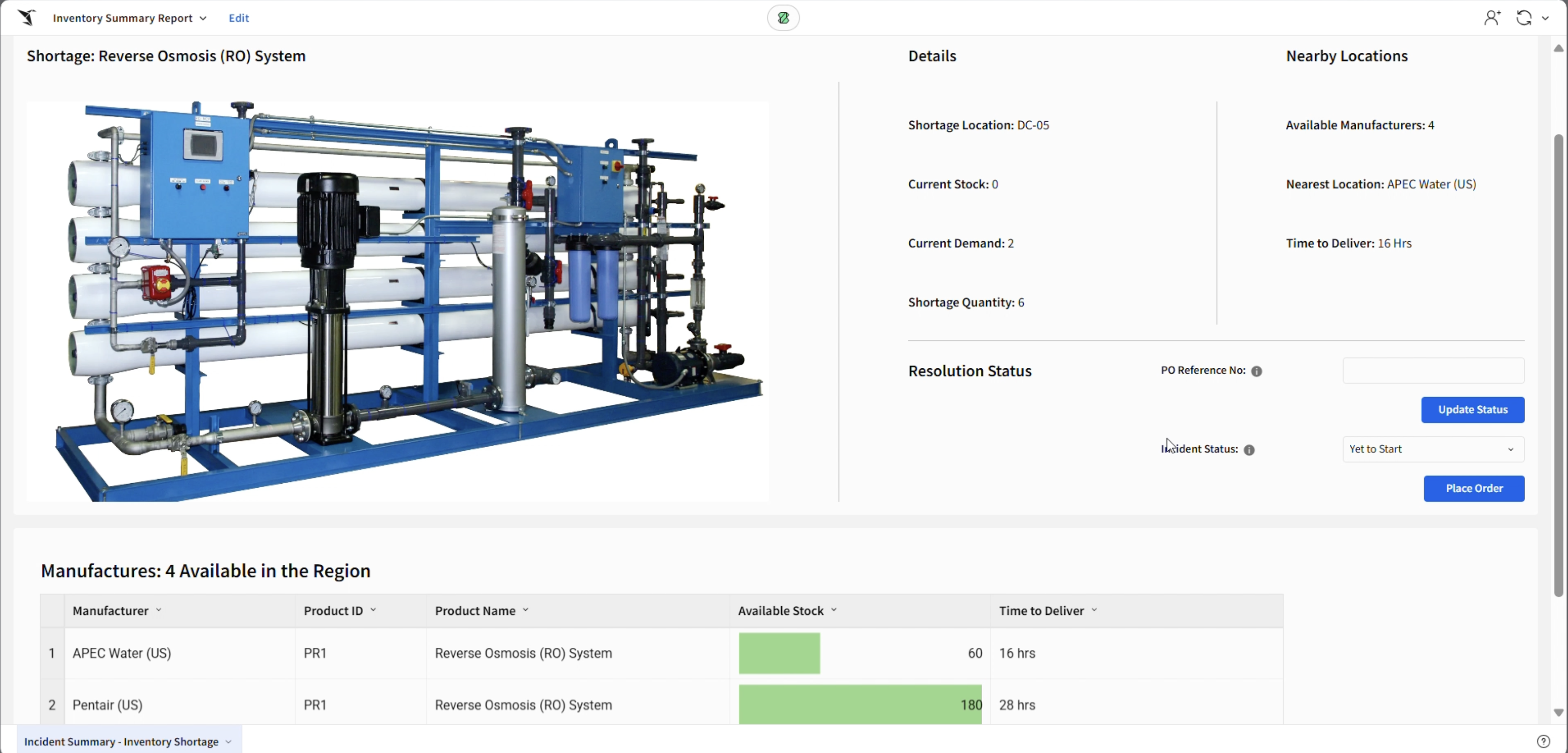

When investigating, the technician identifies the cause: the sensor monitoring the machine is overheating due to torque variations, an anomaly that requires immediate attention. Checking the Sigma supply dashboard reveals the sensor is unavailable in inventory, prompting the technician to place a replacement order immediately through the integrated system.

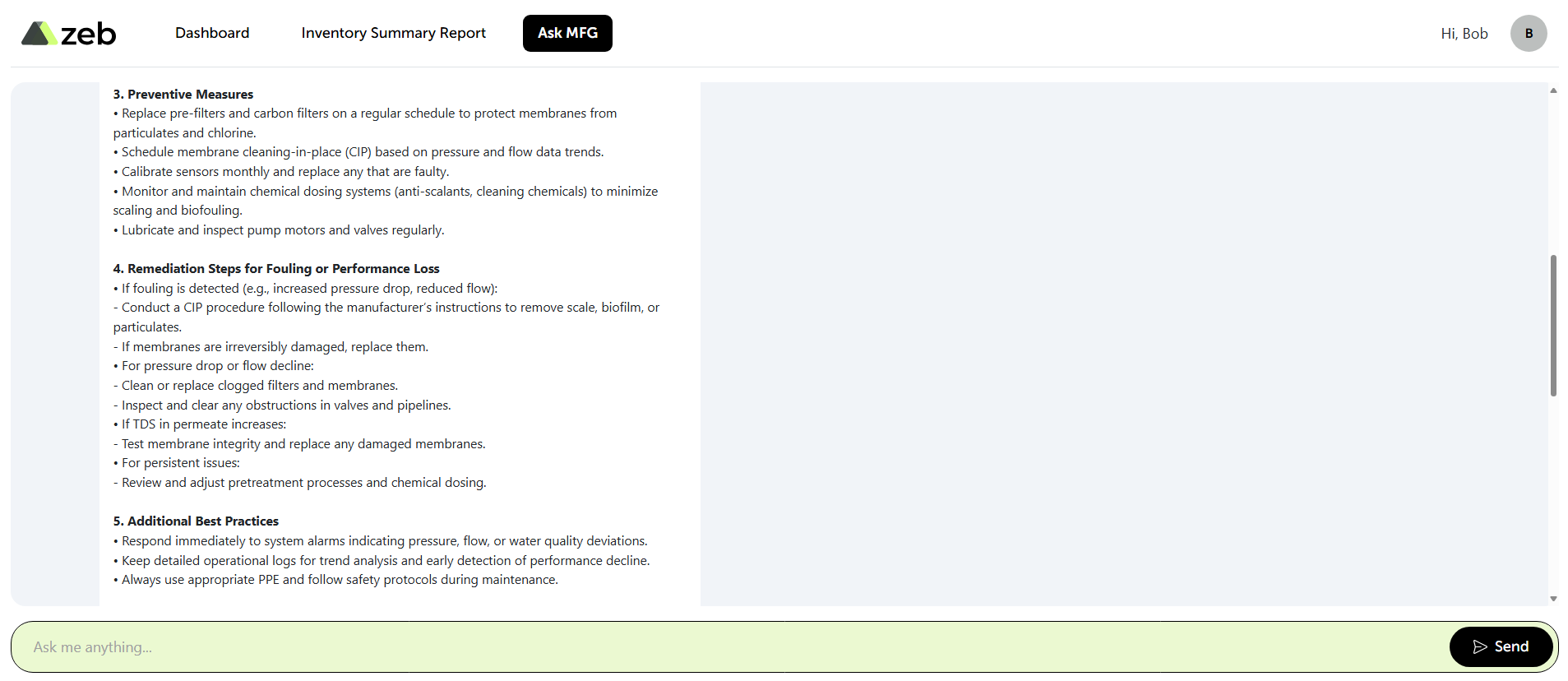

Throughout this process, Agent Bricks acts as a retrieval-augmented assistant, leveraging its Knowledge Assistant and Multi-Agent Supervisor capabilities to enable the technician to:

- Quickly understand the root cause from live telemetry and historical maintenance logs

- Access actionable, prioritized guidance without digging through multiple documents

- Make informed decisions to resolve issues efficiently

Step-by-step workflow:

- Anomaly detected on Machine ID: M1.

- Teams alert generated with next-best-action using Agent Bricks.

- Technicians have the ability to ask questions on notes shared by Agent Bricks for guidance.

- Root cause identified: sensor overheating due to torque.

- Replacement order promptly placed using Databricks Apps, which sent the data back to the ERP system.

- Issue resolved efficiently.

This real-time example demonstrates how multi-agent support, AI/BI analytics, and integrated alerts empower field technicians to resolve high-impact issues quickly, reduce unplanned downtime, and keep manufacturing operations running smoothly.

This scenario reflects the kind of capabilities highlighted in Databricks’ partner demo drive, showcasing how Agent Bricks’ AI-driven multi-agent system can transform maintenance operations in real-world manufacturing environments.

Next Steps

While the current system drives major improvements in troubleshooting speed and accuracy, it’s being embedded in mobile tools or technician handhelds. Integration into existing technician mobile apps and line management dashboards is the logical next step, to make recommendations even more accessible during site visits.

Impact

Agent Bricks transforms manufacturing maintenance, empowering technicians to resolve high-impact issues with clear, explainable prioritization and guidance. By automating root-cause analysis and making technical knowledge instantly accessible, the solution increases uptime, reduces manual escalation, and streamlines every field call. Intelligent maintenance is now within reach—driven by data and delivered by AI.