Supply chain visibility and operations can quickly spiral out of control, with siloed data sources leading to disconnected datasets and inconsistent reporting causing delayed shipments, supplier risks, and skyrocketing costs becoming the norm. These organizations must contend with a fast-moving supply chain and logistics industry while addressing critical data challenges caused by complex external market conditions and low margins.

In one moment, you’re dealing with insufficient inventory, delayed shipments, and incorrect demand forecasting and pricing prediction leading to costly mistakes, excess inventory write-offs, un-optimized route planning or missed revenue opportunities. These offsets are driven by a lack of data maturity in organizations, including:

Continue Reading

- Fragmented data sources with no single source of truth, resulting in inconsistent insights

- Lack of data quality and integrity across multiple datasets, affecting decision-making

- Absence of robust data governance and security frameworks to ensure data integrity

- Delayed data delivery, preventing real-time or near real-time operational visibility

- Inability to reconcile financial datasets effectively, impacting demand forecasting

Companies in this space have a critical need to scale their data estate and infrastructure to handle increasing data volumes, accelerate data delivery, and quickly adapt to internal (new integrations, dynamic metrics) and external changes (market conditions, margins) to their data ecosystems. Lastly, ensuring the right “checks and balances” and reconciliations to financial datasets is crucial for maintaining data integrity, ensuring accurate demand forecasting, and improving visibility operations.

The Common Roadblocks to Supply Chain Visibility

One of the major obstacles in supply chain management is the fragmentation of data. Companies use different systems for transportation management (TMS), enterprise resource planning (ERP), Financial systems, and external market data via data shares from third-parties or their own partner ecosystem. These systems often don’t integrate effectively to form a holistic view of a company’s operations, finances, and resource allocation, leading to fragmented data silos. And as mentioned earlier, without a way to govern and track data assets from source to target and understand its lineage, organizations lose crucial insights into their operations and do not fully understand how to leverage the information in their data.

Adding to the complexity, poor data governance results in inconsistent and unreliable information. Without a structured mechanism for monitoring data quality, forecasting demand becomes a matter of speculation. A single inaccurate data point can disrupt procurement, inventory management, and customer fulfillment and wrong network optimization for routes and shipments, causing delays and lost revenue. Moreover, as cybersecurity threats grow, ensuring data integrity and compliance across a fragmented supply chain becomes increasingly difficult and unmanageable.

While automation offers significant potential to solve many supply chain issues, most companies struggle with implementing real-time alerts or automated responses due to a lack of appropriate infrastructure. Without these capabilities, organizations are left reacting to supply chain disruptions instead of proactively mitigating risks. Automated alerts and responses could help companies quickly identify and address issues like inventory shortages, shipping delays, or quality control problems before they escalate into major disruptions.

Similarly, AI-driven predictions hold promise for supply chain visibility, but many organizations face challenges in effectively preparing the data foundation required to help make these AI systems successful. However, without the right data infrastructure, and integration capabilities, companies often fail to harness the full potential of AI in their supply chain visibility operations, leading to disorganized priorities and incorrect decisions.

How zeb’s Databricks Lakehouse Solution Transforms Your Supply Chain Management

To break through these challenges, organizations require a shift towards an integrated, AI-driven and scalable approach.

zeb’s Databricks expertise provides exactly that—a unified, AI-powered platform that brings together all supply chain data into one place providing a single source of truth, data governance, support for both batch and real-time workloads and a foundation for AI and machine learning capabilities.

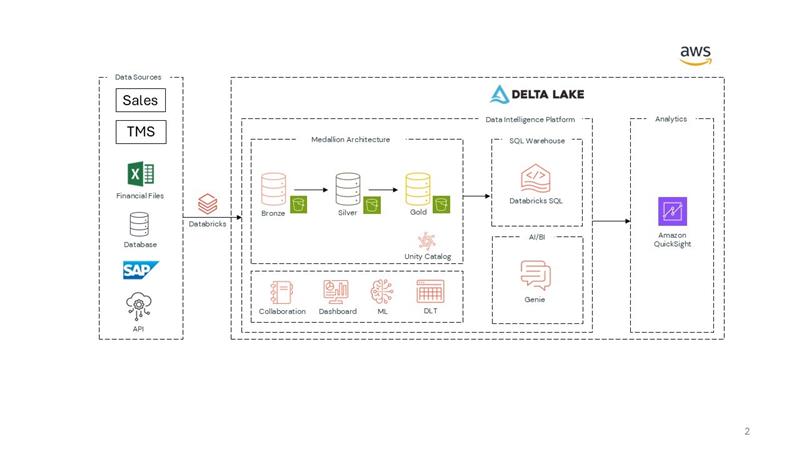

Leveraging the Databricks Delta Lakehouse architecture provides a modern and scalable approach to data integration, combining the best traits of a data warehouse and data lake to comprehensive view of all supply chain entities in the Gold layer, eliminating data silos by integrating everything into a standardized Silver layer, and ensuring a reliable data integration into the Bronze layer eliminating data silos and ensuring there is a unified repository of all data sources in one view. By seamlessly integrating TMS, ERP, finance, and external market data, organizations gain real-time insights into their supply chain visibility and operations.

Unity Catalog adds a data governance layer to track all data movement and objects in your Databricks workspace with support for security and compliance via role and attribute-based restrictions on your data.

zeb’s Databricks expertise takes supply chain visibility a step further by leveraging the Data Intelligence Platform using Mosaic AI for AI-powered predictions and demand forecasting. With Mosaic AI and MLflow, businesses can anticipate potential shipment delays, optimize carrier selection, and refine demand forecasting. These AI-driven capabilities not only reduce costs but also enable more informed decision-making, allowing organizations to become more proactive rather than reactive.

Data Integrity and Security

Accurate data is the foundation of better decision-making, and zeb ensures that data quality is consistently maintained across the supply chain. Through Lakehouse Monitoring, businesses can implement robust data validation processes that ensure consistency and reliability. Moreover, governance with Unity Catalog offer role-based (RBAC) and attribute-based access control (ABAC), along with metadata management and lineage tracking, enhancing data security and compliance.

Leverage Agentic AI to Derive Insight into Supply Chain Operations

In 2025, leveraging Agentic AI frameworks that rely agents built on Databricks to enhance decision-making and operational efficiency will become a game changer for organizations in this space. These specialized agents are built with deep understanding of your own data’s knowledge base including operations, inventory management, transportation routes, carrier networks, and shipment tracking. Each agent is equipped with relevant data and expertise in its specific area.

At the core of this system is an orchestrator agent, which acts as an intelligent interface between users and the specialized agents. When a user poses a question in natural language about any aspect of the supply chain, the orchestrator interprets the query, identifies the most relevant domain, and directs the inquiry to the appropriate specialized agent. This agentic AI framework, powered by Databricks, enables both business users and technical teams to gain rapid, accurate insights across the entire supply chain ecosystem, facilitating more informed and timely decisions in an increasingly complex operational landscape.

Optimizing Supply Chain Networks with an Advanced Suite of Accelerators

For organizations looking to optimize their supply chain networks further, zeb’s suite of network optimization accelerators provide a strategic advantage. By leveraging AI-driven models and real-time analytics, businesses can streamline operations, reduce costs, and improve overall efficiency. Our frameworks include scoring the carrier and shipment for each lane and area is essential for optimizing logistics performance. And pricing prediction at the carrier level enables more accurate and competitive rate setting.

A Resilient, Efficient Supply Chain is Within Reach

Supply chain visibility isn’t just about knowing where shipments are—it’s about having the right data, at the right time, across all systems. Businesses need a connected, intelligent ecosystem where data flows seamlessly across systems, enabling proactive decision-making.

With zeb’s and Databricks solution, businesses can break free from fragmented data, avoid inaccurate forecasts, and transition from reactive to proactive supply chain management. It’s time to gain the control and clarity your supply chain deserves. Our frameworks leverage data attributes related to selecting the right route, lane, and carrier and can help identify the optimal margin and determine when to prioritize upselling versus downselling.

Partner with zeb to build a seamless, data-driven supply chain ecosystem.